I. Material

Lightweight conveyor belts are made from diverse materials, including PVC (polyvinyl chloride), PU (polyurethane), rubber, silicone, and more. Different materials exhibit unique properties and are suited for specific application scenarios.

- PVC Conveyor Belts: PVC belts offer excellent wear resistance, corrosion resistance, tensile strength, and flame retardancy. They are cost-effective and widely used in general material handling scenarios.

- PU Conveyor Belts: PU belts provide superior wear resistance, oil resistance, chemical corrosion resistance, and tear resistance. Their elasticity makes them ideal for applications requiring high friction coefficients.

- Rubber Conveyor Belts: Rubber belts feature strong abrasion resistance, high-temperature resistance, and corrosion resistance. With high tensile strength, they are suitable for heavy-duty material transportation and high-temperature environments.

- Silicone Conveyor Belts: Silicone belts excel in high-temperature resistance, corrosion resistance, and insulation properties. Their flexibility makes them suitable for precision material conveying.

II. Processing Methods and Techniques

The production of lightweight conveyor belts involves the following key stages:

- Raw Material Selection and Formulation: Materials such as PVC, PU, or rubber are selected and formulated based on the belt’s intended use.

- Mixing and Calendering: Raw materials are mixed uniformly, then processed through a calender to form sheets of specific thickness.

- Molding and Vulcanization: The sheets are cut and shaped to the required dimensions. The shaped belts undergo vulcanization in a curing tank to enhance strength and elasticity.

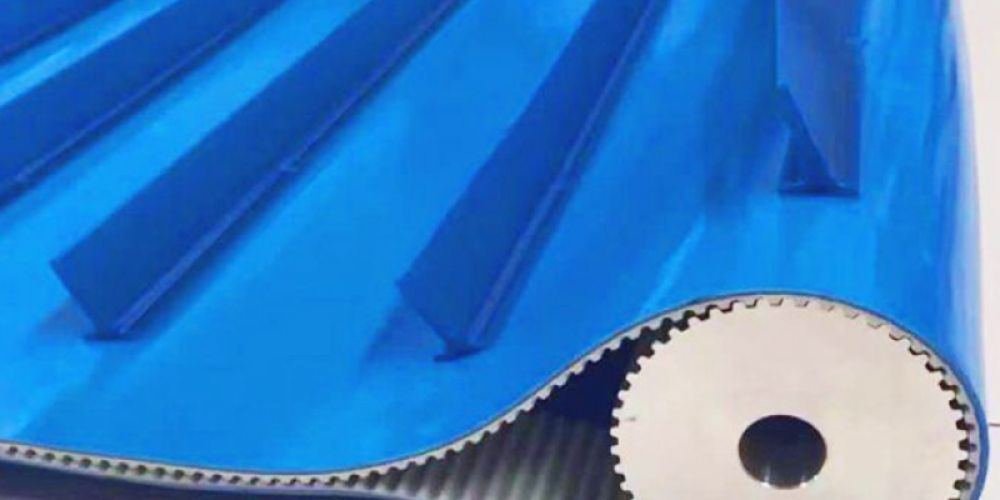

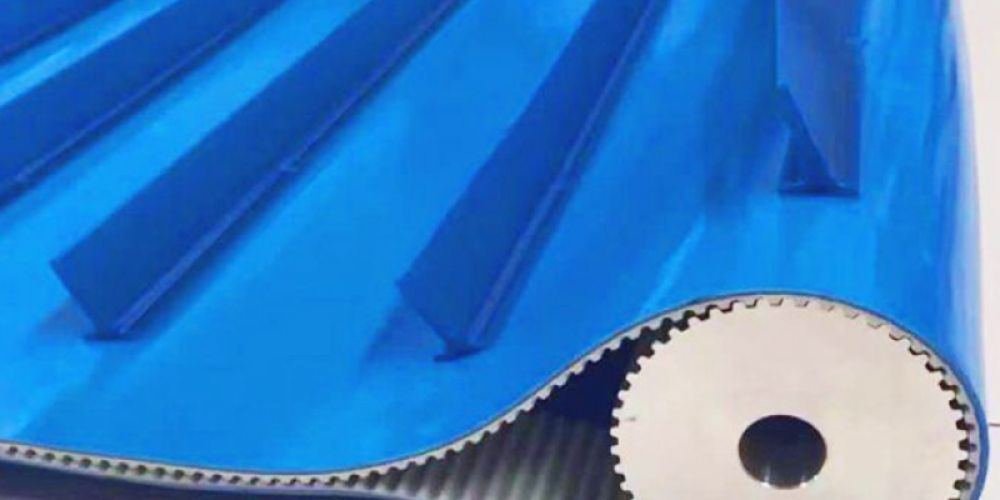

- Surface Treatment and Finishing: Surface treatments like polishing, printing, or labeling are applied. Specialized processes such as perforation, grooving, or adding cleats may also be performed.

- Quality Inspection and Packaging: Finished belts undergo rigorous quality checks to ensure compliance with standards. They are then packaged for storage and transportation.