1. Thickness:

- The standard thickness typically ranges from 1-8 mm, which meets the needs of most industrial applications.

- Custom thicknesses can be produced for special requirements, with the maximum currently achievable thickness being 12 mm.

2. Color:

- Common colors include white, green, black, blue, dark green, gray, and red.

- Custom color matching (based on color charts) is available for large-volume orders requiring unique shades.

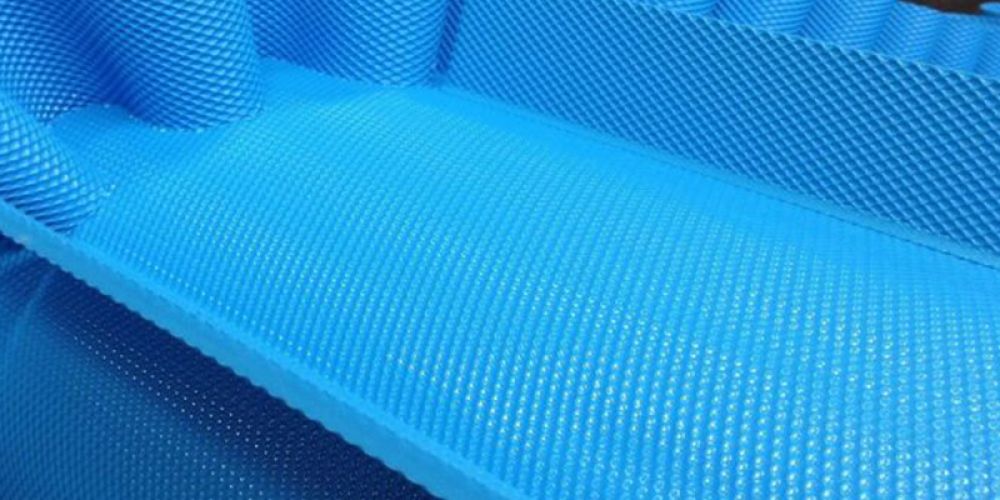

Surface Types: Smooth vs. Patterned

PVC conveyor belts are categorized into smooth-surface and patterned-surface types, differing in surface/backing textures. The choice depends on the operating environment and specific functional requirements, as they vary significantly in application, wear resistance, adaptability, and frictional properties.

1. Smooth-Surface Belts:

- Ideal for horizontal conveying of materials.

- Features: Smooth texture, lower friction.

2. Patterned-Surface Belts:

- Designed for specialized applications. Examples include:

- Green grass-pattern belts: Suited for inclined conveying.

- Green chevron-pattern belts with guide strips: Enables high-speed inclined conveying.

- Other patterns like straight stripes or guide stripes cater to diverse conveying needs.

Additional Customizations

PVC conveyor belts can also be tailored with properties such as anti-static, oil-resistant, or high-hardness features.