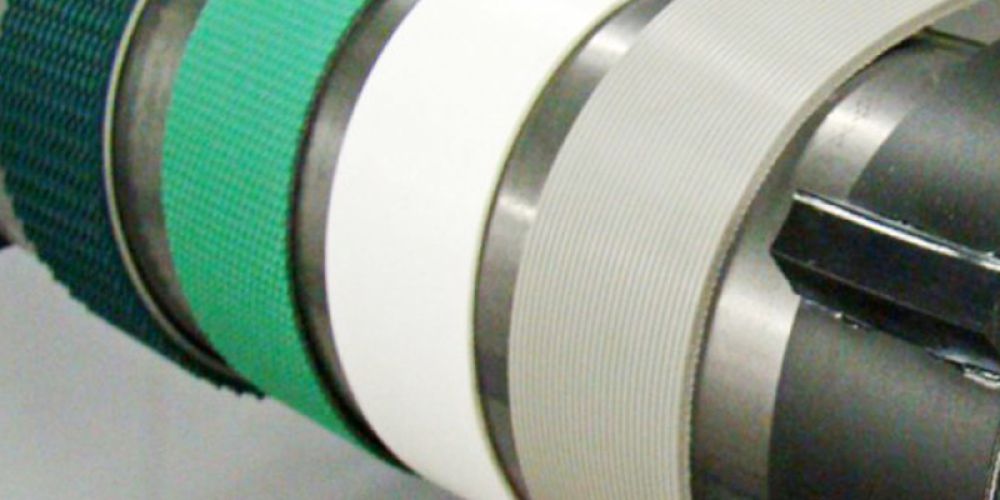

Light-duty conveyor belts can be categorized in various ways based on material and application. Common types include PVC conveyor belts, rubber-plastic composite belts, PU conveyor belts, etc. PVC belts feature diversified thicknesses, multiple color options, and various splicing methods, making them widely applicable in food processing, pharmaceuticals, electronics, tobacco, printing, packaging, and textile production lines. Rubber-plastic composite belts and PU food-grade belts with distinct surface patterns are suitable for ascending transportation of bulk materials and powders. Specially patterned belts offer anti-slip properties for specific scenarios and specialized material handling. Through special processing, these belts can also be customized into guide belts, elevator belts, and flanged edge belts.

Common materials for light-duty conveyor belts include PVC, PU (polyurethane), silicone, and PTFE (polytetrafluoroethylene). These materials typically exhibit non-toxic characteristics, odorless properties, corrosion resistance, and wear resistance, meeting operational requirements across various working environments. PVC and PU remain the most prevalent materials. PVC conveyor belts demonstrate excellent oil resistance, acid/alkali resistance, and hydrolysis resistance, making them suitable for food, pharmaceutical, electronic, and tobacco industries. PU conveyor belts offer superior wear resistance and temperature tolerance, ideal for printing, packaging, and textile applications. Silicone belts are primarily used in high-temperature, high-humidity environments like ovens and baking chambers. PTFE belts provide exceptional high-temperature resistance for thermal material handling.

In summary, material selection should align with specific operational requirements and environmental conditions to ensure optimal performance and safety. Maintenance of light-duty conveyor belts involves two primary aspects:

I. Maintenance Management: